Elevator apparatus fiber laser cutting machine with laser power

800W

New design

1. Machine general introduction

1) Machine Stable running: adopting the top world import fiber

lasers, stable performance, and key parts can reach 100,000 hours,

high efficiency for photoelectric conversion: Compare with CO2

laser cutting machine, fiber laser cutting machine has three times

photoelectric conversion efficiency,the most advanced Europed laser

source with high photoelectric conversion efficiency rate up to

30%, the lifetime of the key parts can reach 100,000 hours, machine

no maintenance, no consumable parts.

2) Machine Low running cost: Save energy and protect environment, low maintenance: fiber line transmission no need reflect lens, save

maintenance cost, World famous brand laser cutting head, ensure good cutting effects

and high precision.

3) Easy operations: fiber line transmission, no adjustment of

optical path, super flexible optical effects: compact design, compact and easy to

flexible manufacturing requirements, economic price but top quality, especiall for Advertising industry.

4) highly strengthened steel bed annealed to ensure high speed with

no deformation at least 20 years.

5) Precise rack bilateral servo motor driving system with highest

response speed, machine idel travel speed up to 100 meters/min.

2. Machine main features:

German high performance reducer, gear and rack transmission which

ensure the cutting precision and the stable performance, our 800W

CNC fiber laser cutting equipment uses a moving gantry structure,

imported high-precision screw and linear guide, smooth

transmission, high precision , the X, Y, Z axes are imported from

Japan servo motor, high-precision, high- speed, high-torque, high

inertia, stable performance and durable.

We ensure the machine's high speed and acceleration, bed with the

moving beam as a whole welded structure, roughing after annealing,

and then the vibration aging treatment, can completely eliminate

the stress of welding and machining, good rigidity, high accuracy

can be maintained for a long time does not deform, we adopt the

laser cutting control special function modules, powerful,

human-machine interface, easy to operate based on the Windows

operating system, fiber laser cutting machine CNC system

integrated, independent research and development of personalized

nesting software.

CNC cutting machine to achieve “full-time cutting, efficient

cutting and high - nesting rate cut " core technology is the

fundamental guarantee of effective material savings, improve

cutting efficiency , with imported high - precision electronic

control proportional valve, precise control of the cutting

auxiliary gas pressure, in order to achieve the best cutting

results.

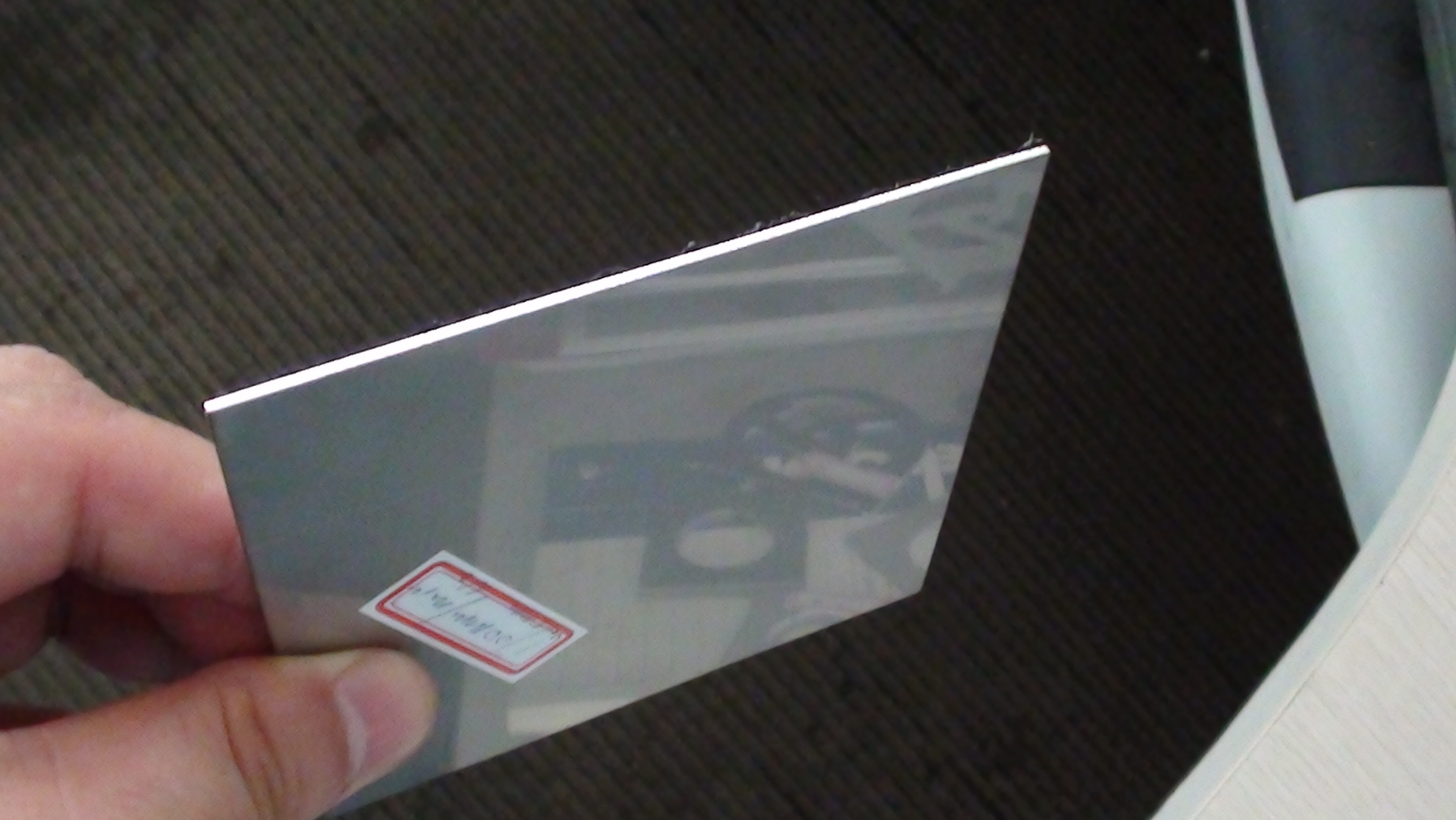

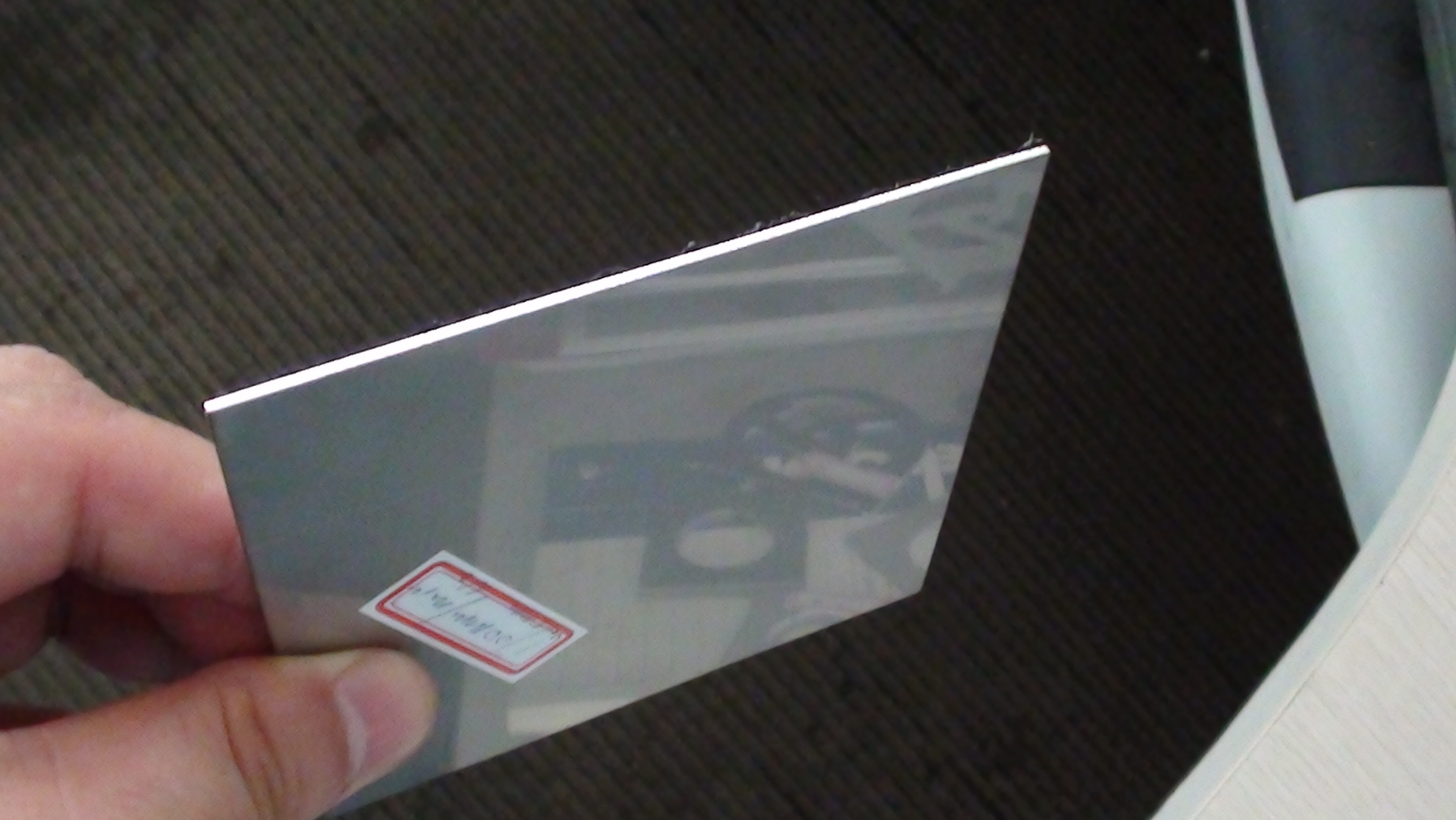

3. Application materials

Stainless steel, carbon steel, alloy steel, silicon steel, spring

steel, aluminum, aluminum alloy, galvanized sheet and other metal

pipes and tubes.

4. Machine application field

Widly applied to metal-sheet processing, stainless steel decorative

engineering, advertising trademark and advertising character,

high/low voltage electrical cabinet, kitchenware, metal crafwork,

auto parts, farm machinery, medical instrument, sports

equipment,environmental protecion equipment, elvvator apparatus,

central air conditioning, metal craftwork, hardeware, tool and

gauge etc...

5. Suntop fiber laser cutting machine main cutting functions:

No. |

Functions |

Main Descriptions |

| 1 | Height following | Torch move up and down according to plate height |

| 2 | Power control | Laser power controlled according to slope |

| 3 | Reverse function | Reverse to execute NC program |

| 4 | Breakpoint return | Return to breakpoint after recovery |

| 5 | Multi piercing | Pulse, blasting, progress, high-speed |

| 6 | Lead line | Set lead line parameter |

| 7 | Auto edge-seeking | Find cutting piece coordinate automatically |

| 8 | Leapfrog function | Leapfrog to improve cutting efficiency |

| 9 | Common line | Common line to improve the cutting efficiency |

| 10 | Marking function | Machine can do any shape laser engraving on plate |

| 11 | Nesting function | Software can be automatic layout, saving material |

| 12 | Auto alarm | If machine has problems or parts disconnected, the machine software

will show error code automatically, so that the operator can find

the solution very easy and quickly. |

6. Cutting speed data (only for reference, the actual speed depend

on the actual materials)

Thickness (mm) | Materials | Max. cutting speed (M/min ) |

1 | Carbon steel | 14 |

2 | 8 |

3 | 3.5 |

4 | 2 |

8 | 1 |

10 | 0.6 |

1 | Stainless steel | 15 |

2 | 6 |

3 | 2 |

4 | 1 |

6 | 0.5 |

1 | Aluminum alloy/brass | 3.5 |

3 | 1.2 |

7. The machine’s main technical parameters

Specifications | Parameters |

Max. laser power | 800W |

Laser wavelength | 1064nm |

Effective processing area | 1500*3000mm (other size can be customized ) |

Positioning | Red light indication |

X,Y axis repeat positioning precision | ±0.03mm |

X/Y axis positioning accuracy | 0.05mm/m |

Z axis route | 120mm |

X/Y max axial acceleration | 1G |

Max. loading weight | 500KG |

Protection level of main power | IP54 |

Max. cutting thickness | ≤10mm ( the real thickness depend on the actual materials ) |

Cutting software Support format | DXF and PLT which outputted from the Auto CAD or CorelDraw software

) |

Total power consumed | ≤8KW |

Power supply | 3 phases , 4 wires AC, 380V, 50HZ/60HZ/60A |

The Auxiliary gas | O2 , N2 and compressed air |

Machine whole weight | 3500KG |

Machine loading method | 20'GP container |

8. Machine’s main configurations

Item | Name | Specifications | Qty |

1 | ST-FC3015-800E | 3000*1500mm | 1 set |

2 | Fiber laser source | 800W ( Raycus or USA nLIGHT) | 1 |

3 | CNC control system | LASERCUT&CYPCUT | 1 |

4 | Laser cutting head | Swiss Raytool | 1 |

5 | Water chiller | Wuhan China | 1 |

9. Machine rough running cost:

a) Total power consumption

| Machine parts | Power (KW) | Power consumption(KW/H) | Note |

| Laser generator | 2 |

≤11.4*60% = 6.7 | Due to the electricity cost different in every country, so I can

only give total power consumption, couldn’t give total electricity

price cost |

| CNC machine tool | 5.8 |

| Water chiller | 3.6 |

b) Machine gas consumption

| Gas type | Consumption (L/hour) | Remark | Note |

| Oxygen | 6L/Hour | Calculated based on 1mm carbon steel sheet | Due to the gas price different in every country, so I only can give

the rough gas consumption per hour |

| Nitrogen | 20L/Hour | Calculated based on 1mm stainless steel sheet |

C) Machine consumable parts

Consumable parts name | Life time ( hour) | Unit price (USD/piece) | Total cost (USD/hour) | Note |

| Protection mirror | ≥240 | 60 | 0.25 | If the working environment is good, the consumable parts lifetime

will be more longer |

| Nozzle | ≥600 | 35 | 0.058 |

| Total | USD0.3 /hour |

D) Machine rough total running cost

| Item | Power consumption (KW/hour) | Consumable parts

| Gas consumption | Note |

| O2 gas cutting | 6.7 | USD0.3/hour | 6L/hour | Based on 1mm carbon steel |

| N2 gas cutting | 6.7 | USD0.3/ hour | 18L/hour | Based on 1mm stainless steel |

Remark: if use the compressed air to cut stainless steel will save much

gas cost.

10. The laser cutting samples for different materials for

reference: